Page 1 of 1

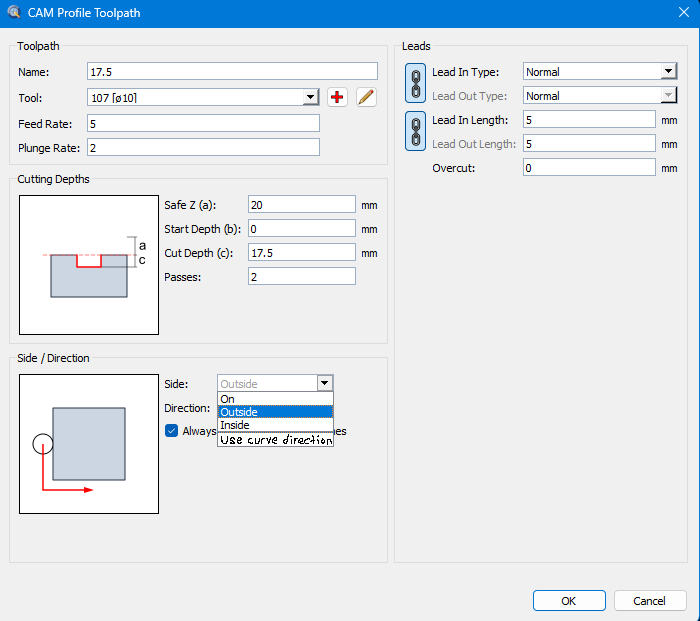

Feature request: Option to use the direction of the curve for Side/Direction toolpath

Posted: Fri Jun 14, 2024 9:49 am

by artisanicview

It will be more useful to have an option called "Use curve direction" in the "Side" dropdown menu, than the actual workflow, that don't take into account the direction of the curve.

Using the proposed "Use curve direction" will make redundant the "Direction:" dialog from underneath (only when used this strategy).

- Use Direction of the curve.png (31.25 KiB) Viewed 60042 times

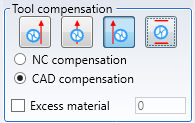

For another CNC machine I do use a CAM program called Maestro, where if I do import a DXF file and when I do set the toolpaths, it is always taking into consideration the direction of the curve. I only need to set the On/Left/Right compensation and that's it.

- Maestro_Tool_Compensation.png (9.78 KiB) Viewed 60042 times

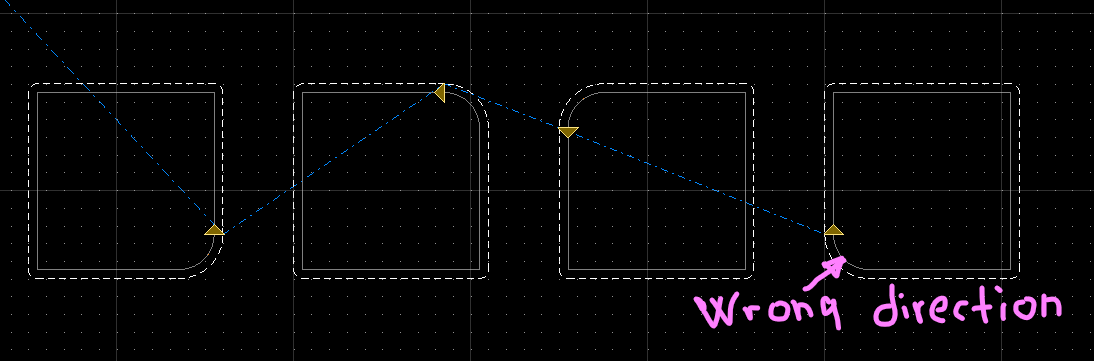

The current approach that misses this feature can result in undesirable result like the one example below, where one of the contours needs to be cutted inside.

- Wrong_toolpath_direction.png (19.17 KiB) Viewed 60042 times

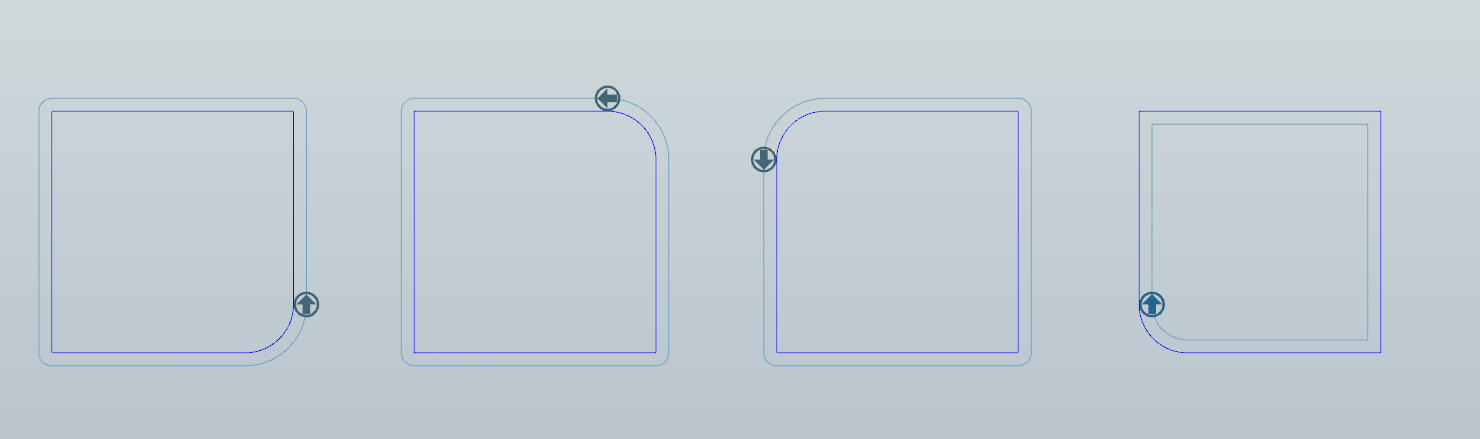

And this is how looks in Maestro, the same DXF layer:

- Maestro_Toolpath.png (13.9 KiB) Viewed 60038 times

Re: Feature request: Option to use the direction of the curve for Side/Direction toolpath

Posted: Fri Jun 14, 2024 10:31 am

by CVH

Yes and no.

Your 'Wrong direction' is correct for outside compensation.

When milling there are two distinct approaches.

- Conventional milling.

- Climb milling.

Both can be used as inside and as outside.

There are thus 4 different paths.

- Conventional outside.

- Conventional inside.

- Climb outside.

- Climb inside.

Agreed that this not an issue for Plasma, Laser, WaterJet, ... Where there is no rotating cutting tool.

And it is less of an issue in woodworking.

Still, when slot routing in wood there will be a neat edge and a less neater edge depending many variables.

The type of wood, the cutter type, the stiffness of your setup, SPEED, FEED, available spindle power and so on.

It is then the idea that neat edge is the cutter side facing your part.

And that the less neater edge is facing the spoil ... The left over.

So it is wrong to say that the arc direction controls the compensation side.

It can when you only use conventional milling or only climb milling.

On top, QCAD stores arc direction as a special parameter, DXF arcs are always conventional ... CCW.

The first 3 paths by QCAD use conventional milling, the fourth is climb milling (If the cutter turns CW)

There is nothing really 'Wrong' with that.

Your examples of Maestro all use conventional milling.

For most woodworking that may produces the neatest edge facing your part but that is not a certainty.

QCAD/CAM is not limited for SCM woodworking.

Again, the CAM Profile Toolpath dialog can be tweaked from within a custom postprocessor.

Regards,

CVH

Re: Feature request: Option to use the direction of the curve for Side/Direction toolpath

Posted: Fri Jun 14, 2024 10:38 am

by CVH

The real question here is why not stick to Maestro?

Why fixing something that works?

It is not the first time that this pops up.

Regards,

CVH

Re: Feature request: Option to use the direction of the curve for Side/Direction toolpath

Posted: Fri Jun 14, 2024 12:23 pm

by artisanicview

The real question here is why not stick to Maestro?

Unfortunately I do need to run a CAD/CAM software on an old CNC machine that have WindowsXP as OS and there Maestro simply can't run. The CAD/CAM software that it is installed on the machine by manufactures it is from the stone age, I don't like it because it is very old and rudimentary. So I do remembered that I used some years ago QCAD for other job, and I tested if it works on that XP machine and it does (the legacy 32bit version of QCAD).

I also do use another, more modern CNC machine where I do have the Maestro installed, unfortunately the Gcode it is quite different between this two machines, so I do try to use QCAD/CAM to generate Gcode for the older machine. Hopefully makes sense.